At Terajoule and JL Metals we adopt a collaborative work culture that is motivating, exciting and adaptable to the needs of our clients, our partners, and our employees. Our greatest asset is our culture and positive, goal-focused team.

As an architect of original and innovative solutions for the mineral processing industry, Michael personally conceives, develops and delivers increased levels of efficiency and effectiveness never before seen by expanded Perlite producers.

General Manager of Normiska Corporation, VIL Vermiculite Perlite and vermiculite mineral processing facility. Managed a staff of 20 employees where we transformed raw ore into expanded minerals in high temperature furnaces for the construction, industrial and agricultural markets. READ MORE…

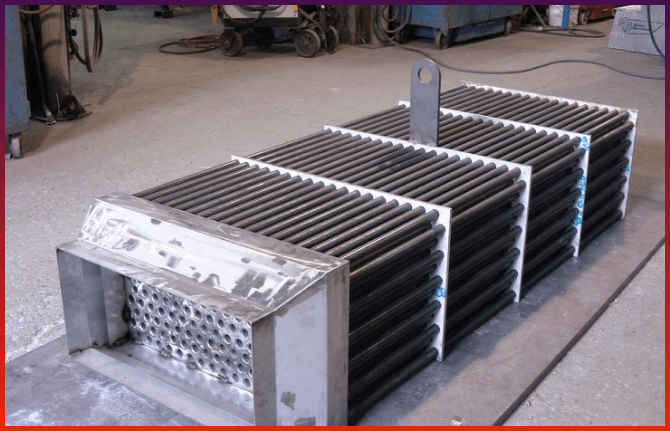

At JL Metals we consider ourselves the full system steel parts manufacturer for everyone. Our experienced staff and diverse metal parts manufacturing capabilities allow us to serve a multitude of market segments including automotive, agricultural, HVAC, office furniture, material handling, construction, energy, forestry, mining, industrial and transportation to name a few. We know the stringent requirements of manufacturing across these industries, and we will ensure that each system is produced to exacting standards and specifications, on schedule. READ MORE…

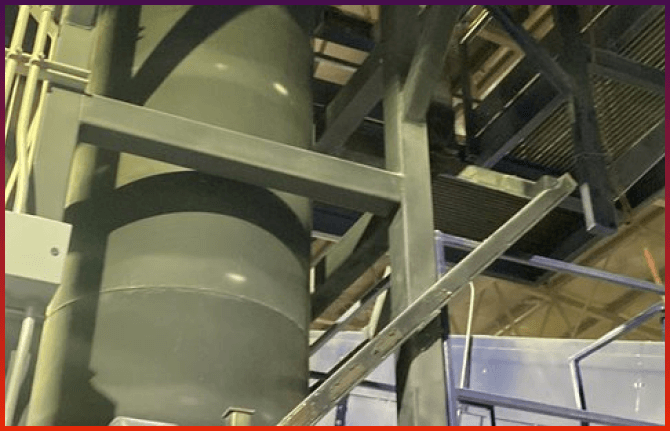

Traditionally, furnace operators had one air stream supplied to the burner, be it pre-heated air or ambient. Terajoule uses a purpose built heat exchanger to freely transfer waste heat remaining after the expansion process to the combustion air. In this way we truly recover lost heat and a side benefit is that the exhaust air is cooler which protects the bag house and fan.

Terajoule is an engineering company devoted to saving energy, money and greenhouse gas emissions for its clients.

Terajoule was founded in response to the challenges of ever-increasing fuel prices and stagnant innovation from major furnace manufacturer’s approach to fuel efficiency and operational design.

We challenge complacency in innovation, cost competitiveness and customer service. We are invested in our clients’ success, and redefining their financial and operational goals. We strive to keep our clients competitive.

Terajoules Saved

Dollars Saved Annually

tCO2e Eliminated Annually

As an architect of original and innovative solutions for the mineral processing industry, Michael personally conceives, develops and delivers increased levels of efficiency and effectiveness never before seen by expanded Perlite producers.

General Manager Normiska Corporation, VIL Vermiculite Perlite and vermiculite mineral processing facility. Managed a staff of 20 employees where we transformed raw ore into expanded minerals in high temperature furnaces for the construction, industrial and agricultural markets. Responsible for production, eastern Canada sales, staff and all issues related to operations including maintenance, energy, environmental and administration PremiAir Technology Inc. Project engineering, field supervision High temperature drying hoods and heat recovery in pulp and paper industry. Manager Barr-Rosin, SEAManager Barr-Rosin, SEA GEA Niro A/SGEA Niro Stationed in Singapore, Michael was responsible for the Barr-Rosin drying business throughout the countries of South East Asia.

At JL Metals, the foundation of client relationships is built around our mantra ‘Strength Through Partnership’. We have a broad range of resources and capabilities that allow us to provide exceptional quality products, manufactured to exacting client specifications at pricing that demonstrates value to our customers.

JL Metals was established in 2010 and has been servicing clients successfully in North America and internationally ever since. We are a continuously growing and evolving company that strives to have leading technologies and capabilities in order to provide industry leading service at all times.