Instead of the standard tuyere failing by thermal stress cracks every 6-12 months, our tuyere fails by physical erosion of the firing cone. Notice the wrinkled surface of the firing cone and the worn-out cone. Surprisingly, it still worked well even in this condition! This was after about 2 years of use, 6,000 hrs/year. The temperature gradient across the cone puts enormous stress on the metal and produces micro cracks over time. Upset conditions, …READ MORE…

We have helped our clients with:

Energy efficiency Improvements

Operational Data Analysis

Identifying opportunities for efficiency gains and product quality improvements

Process optimization

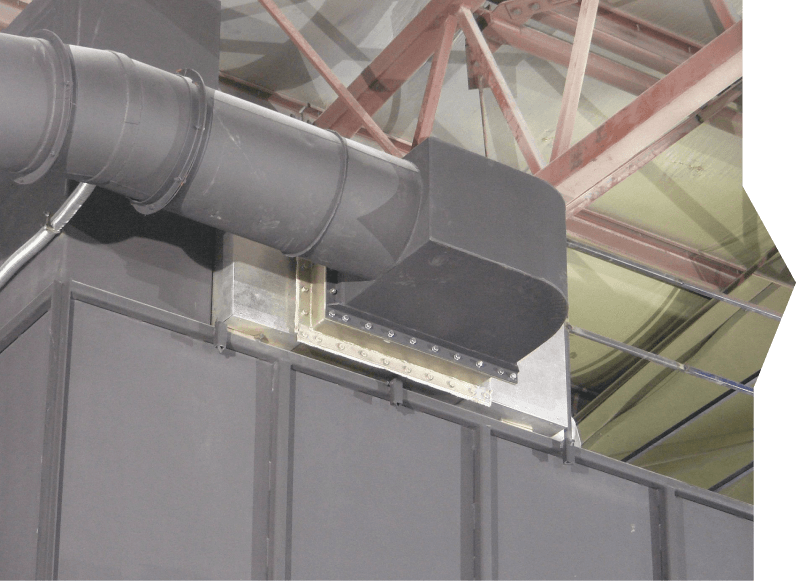

Optimizing airflow and ventilation

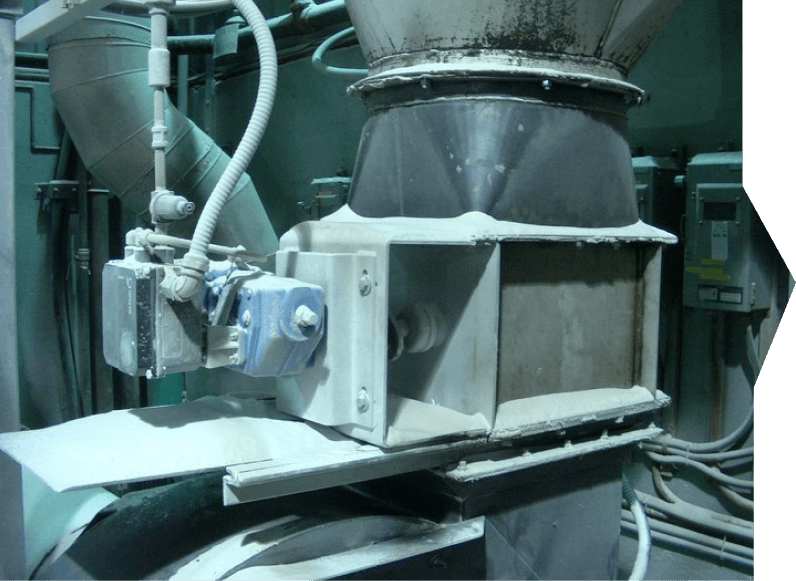

Furnace maintenance and repairs, heat exchanger servicing

It’s crucial for perlite expansion companies to have a team of skilled technicians, engineers, and specialists or access to external technical support providers to address these technical aspects and maintain the furnace’s reliability, efficiency, and safety. Regular preventive maintenance and ongoing technical support can help extend the furnace’s lifespan and reduce operational risks.

Our customers have requested technical expertise in many areas including optimizing burner performance, ensuring proper fuel-air ratios and troubleshooting any combustion issues such as pre-ignition……. READ MORE…

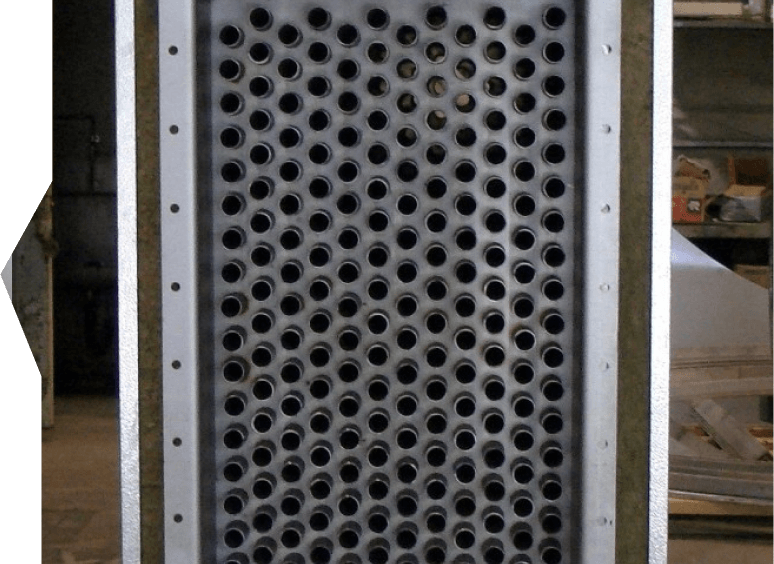

JL Metals is the sole licensed fabricator for all Terajoule proprietary equipment and systems. JL Metals provides quality workmanship with a track record in specialty high temperature alloy materials that are required in the hot sections of a perlite furnace. Our experienced team of draftsmen and fabricators, with access to significant materials inventory are highly adept at taking full systems from concept through design and prototyping to on site deployment at our customers facilities. Custom designed systems specific to your needs and application requirements are fabricated by a team committed to ensuring predicted performance results are realized……..READ MORE…

US Patent #9,791,147

‘Multi Stage Combustion Furnace and Process for the Thermal Expansion of Mineral Particles’

https://patents.justia.com/patent/9791147

Canadian Patent #2,754,312

Canadian Intellectual Property Office

EU Patent Pending via International Patent Treaty

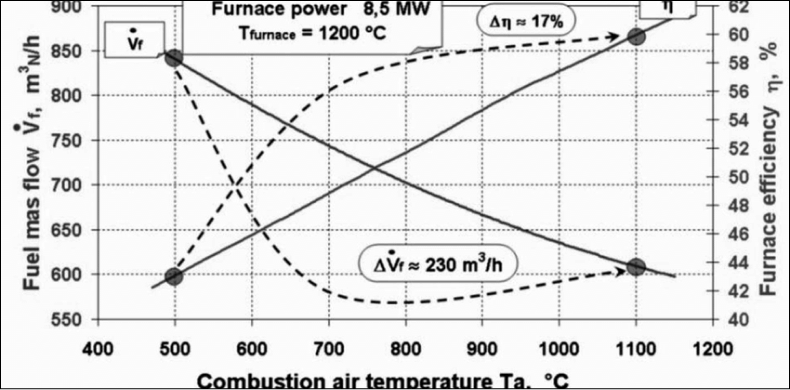

Using this in-house technology we are able to reduce the air flow from typically 1.25-1.5 times the stoichiometric ratio to just a few percent above. These measures combine to give a stable, controllable flame and a higher performing and higher profitability furnace operation.

The Terajoule ERS does not create a temperature gradient is huge across the walls of the furnace. These temperature differential sets up internal stresses within the metal – expansion on the hot side and contraction on the cold side. Cracks form over time to relieve this stress leading to a breach in the pressurized heart and poor overall furnace performance.

A window is provided to view the tuyere color and a small reject port vented to atmosphere will provide audible feedback as to the state of the furnace to the operator, enabling corrective action to be taken to prevent a fusing.

Terajoule’s energy audit unlocks your potential for savings and operational gains and provides you with a blueprint for a custom waste heat recovery kit. We can assist your operations with remote analysis of your furnace performance and improvements in the quality of your final product. In addition, we can visit your facility for a reasonable cost and perform a full, no-obligation study which will provide understandable metrics for every aspect of your furnace expansion performance.

In almost all cases, there are improvements which can be realized with straightforward system tuning. Our detailed reports include all current and predicted performance data and recommendations we provide will help you make a well-informed decision. Terajoule can generally guarantee energy savings per cubic foot of perlite and no reduction in yield and production according to a verified Performance Test. Using metrics for as many prior years as possible, our track record proves that production increases and fuel savings have been realized by all customers post Terajoule ERS implementation. We extract and make sense of the data so you understand every aspect of your energy consumption.

Expanding perlite is an energy intensive process making it an ideal candidate for efficiency improvement. It is also a challenging process to maintain in equilibrium on a continuous basis.

Variations in process temperatures, feed rate, air flow, weather, and ore quality all affect overall performance. Problems are noted for lower yield, lower production and higher energy usage. Maintaining stability at optimum points gives higher yield, higher production and lower energy usage on a volume output basis. Using higher air flow than is required negatively affects thermal efficiency. We note that operators tend to choose furnace settings that keep the process running for uninterrupted production. It is customary to use more air flow than necessary to reduce operational problems. A temporary drop in air flow can create mineral fusing or ‘clinkers’ in the furnace which often shuts the process down resulting in lost production.

Terajoule has developed a method of improving thermal efficiency without compromising any of the unit operations. Every furnace that we converted has experienced higher yield, higher production, more operating hours with fewer stoppages and significantly lower energy consumption, all on a volume output basis. Our customized fabrication skills can be used to improve any or all aspects of your process and our years of expertise will help with replacing degraded parts with the most modern and efficient designs.

Instead of the standard tuyere failing by thermal stress cracks every 6-12 months, our tuyere fails by physical erosion of the firing cone. Notice the wrinkled surface of the firing cone and the worn-out cone. Surprising it still worked well even in this condition! This was after about 2 years of use, 6,000 hrs / year. The temperature gradient across the cone puts enormous stress on the metal and produces micro cracks over time. Upset conditions, specially forming agglomerates of molten perlite and obsidian, called ‘clinkers’ (inset picture) can sometimes lead to partial blockage, buckling of the cone and poor production. In that case the remedy is to replace the tuyere. Typical life of a standard tuyere is 6-12 months. Furnace liners, heat exchangers, ore preheaters, ductworks and controls and instrumentation are all elements that can degrade over time and will benefit from Terajoule’s expert design and innovative product portfolio.

Our proprietary, patented technology enables mineral processors to achieve dramatic savings in energy, raw materials (ore) and production time by recovering waste heat and strategically injecting it back into the combustion process at strategic positions. The resulting flame burns brighter, the ore expands further and production output is dramatically improved.

Our goal is to adapt and integrate our ERS system with their existing expansion furnace so strengthening their operations and improving their bottom line through innovative and highly effective combustion technology.

A visual look at the expanded perlite samples after ERS illustrates the clean and dusty nature of the respective product with an undeniable quality improvement provided by the Terajoule converted furnace.

Our customers have requested technical expertise in many areas including optimizing burner performance, ensuring proper fuel-air ratios and troubleshooting any combustion issues such as pre-ignition. We have experience in calibrating and maintaining temperature control systems such as thermocouples, PID controllers and SCADA systems. Furnace maintenance, including refractory repairs, burner maintenance and heat exchanger servicing is an ongoing onsite service we can provide. Our technical team can help design, maintain or optimize your furnace airflow system including fans and ductwork.

JL Metals is the sole licensed fabricator for all Terajoule proprietary equipment and systems. JL Metals provides quality workmanship with a track record in specialty high temperature alloy materials that are required in the hot sections of a perlite furnace. Our experienced team of draughtsmen and fabricators, with access to significant materials inventory, are highly adept at taking full systems from concept through design and prototyping to on site deployment at our customers facilities. Custom designed systems specific to your needs and application requirements are fabricated by a team committed to ensuring predicted performance results are realized. Combining Strength through Partnership, the JL team works with Terajoule engineers in every stage of system specification and build and fabricates all proprietary Terajoule equipment at our facility in Stoney Creek, Ontario. Proudly made in Canada! JL Metals is committed to complete customer satisfaction and to providing quality products and services. An emphasis on quality and quality systems is in the best interest of the customer, the supplier, the employee and the long-term success of the organization. JL Metals specializes in the distribution and processing of steel products, assemblies and fabrication. We are an entrepreneurial business that has found success by identifying a particular business niche and becoming expert in it. Over the years, the company has enjoyed increasing success in leveraging its knowledge of current steel making practices to exceed customer expectations in the aspect of controlling and maintaining inventory costs.