When we implement this kit, called the Energy Recovery System (ERS), we keep the pressure at the furnace venturi as close to neutral as possible, keep air ingress down to a minimum, achieve just the right amount of airflow for ideal combustion, i.e. operate at the stoichiometric air ratio. By doing this automatically, the combustion temperature in the firing zone rises to the optimal maximum and the perlite expands to a higher volume – the perlite produced is about 15-20% lighter which adds to the furnace output for our clients.

To pre-heat the combustion air with the waste heat contained in the hot exhaust and to strategically admit this hot air in a manner that improves overall expansion characteristics. The system uses your existing combustion air fan to move the air against the system resistance with all new interconnecting ductwork between the combustion fan, heat exchanger and manifold. The preheated air is supplied under pressure to the burner, hot air ring and hot tuyere via the manifold. The pressure dissipates to near zero (atmospheric pressure, slightly negative). This allows for an open port on the tuyere without any hot spills or cold ingress of air from or to the furnace.

Shifts half the air flow from the existing burner head to inside the furnace. It is introduced at high speed (over 120 km/h) in the form of a ring jet surrounding the venturi. Now the normal velocity up through the venturi is effectively halved so we draw in much less surrounding air. Brighter and higher temperature results in the combustion zone. Perlite expands to a higher degree.

The hot tuyere is physically robust and dimensionally stable over the entire operating range. We have not had a single tuyere warped or heat distorted in any way under operating conditions so far encountered. Removable tuyere designs typically require replacement every 6-12 months. The Terajoule Hot Tuyere is expected to last at least 4 years or longer.

The hot air ring is a burner cap that delivers preheated air at 300 deg C to fill up the space around the burner head instead of sucking in cold ambient air. This promotes higher temperature combustion.

To produce a ring of pre-heated air around the central air/fuel mixture that blocks ingress of cold air and allows fine tuning of the air/fuel ratio at all times. The hot air ring allows the process to maintain near zero pressure allowing dropouts to flow out without letting cold air in. Fabricated in grade 330/321 stainless steel construction according to temperature zones.

Our system requires a new modulating exhaust air damper to maintain a set air pressure (slightly negative) at the base of the furnace. This prevents hot gas expulsion as well as excessive cold air bleed-in through the reject port. It is a stainless steel damper suitable for dirty/abrasive environment. Controls include a pressure sensor/controller, and an industrial pneumatic piston operator acting on a two blade damper. Expected life is greater than 12 years.

To maintain constant pressure, thus air flow and air/fuel ratio, in the furnace. This control means that the operator can change feed rate, furnace temperature and % excess air and the new exhaust damper will follow the manual changes to always maintain constant pressure in the furnace. The damper is a heavy duty dirty gas design fabricated in grade 304 stainless steel, complete with pneumatic actuator and positioner and closed stuffing box for the twin shafts in lieu of bearings. This is to be fitted to your existing fan after the bag house.

We use a purpose-built heat exchanger to transfer waste heat from the exhaust to the combustion air. It is designed for dirty gas operation where dilute amounts of perlite dust will not eat through the heat transfer tubes. These are made from chromium molybdenum tubes which give good abrasion resistance for about a 10 year lifespan. The heat exchanger preheats the combustion air from ambient to about 600 F.

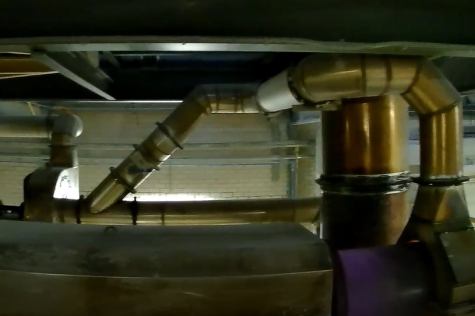

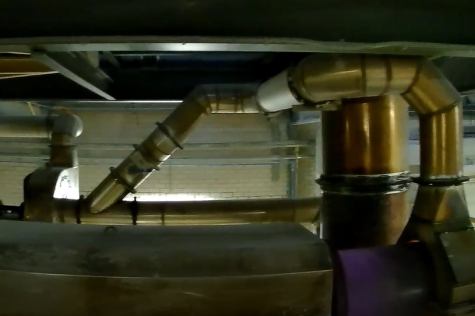

Duct work in mild steel (schedule piping typ.) is required to deliver and return combustion air from the heat exchanger to the manifold. The manifold has built in dampers to direct the required air to the burner, hot air ring and tuyere. Specialized stainless steel flexible duct sections allow for free thermal expansion of the system.

A number of magnahelic pressure gauges, switches and temperature sensors monitor the system for optimal airflow and combustion air temperature. The automatic modulating damper is controlled with a 4-20 mA signal for optimal furnace draft using the baghouse fan. The ERS system integrates easily with existing production management software.

The fluid bed cooler is fitted below the hot box and is designed to cool the expanded perlite in a most gentle manner. The unit features a lower pressurized air plenum, special perforated fluidizing plate, expanded hood to drop the air velocity thereby minimizing dust carryover, exhaust canopy, discharge weir with gate and windows for inspection/viewing. The fluid bed cooler is fabricated in mild steel for the case and 304 stainless steel for the fluidizing plate.

It offers several advantages for cooling expanded perlite: It provides even and consistent cooling throughout the perlite particles, ensuring that they are cooled uniformly. This is important for maintaining product quality and preventing any localized overheating. Expanded perlite particles are fragile and can break if subjected to excessive mechanical stress. Fluid bed coolers typically involve gentle handling of particles, reducing the likelihood of breakage. Fluid bed coolers can also aid in dust control, as the fluidization process can help to contain and manage airborne particles.

The rotary preheater is designed to heat the raw ore from 20-200 °C and thereby bring the ore closer to its glass transition point without losing too much bound moisture – the motive force for expansion. It is well known that a well designed ore preheater will ensure larger expanded perlite, a reduced amount of fines and the mechanical system will smooth and regulates the ore feed into the furnace. The preheater is designed as a counter flow heat exchanger. The ore enters one end through a chute on the endplate into a rotating inner drum having flights to move the ore along and a slope towards the exit allowing for complete ore removal at the end of shift. The hot exhaust gas flows through the space defined by the inner drum and stationary outer case. Inlet and outlet air connections are in the form of a scroll producing helical flow for minimum air resistance.

The hot box gives a dwell time of 5 to 10 min. in hot conditions. This extra time allows for residual perlite growth and hardening. Density below 5 lbs/ft3

The hot box separates the hot perlite from the exhaust air and provides a gentle dwell time of about ten minutes to promote residual granule growth and partial hardening of the perlite. The hot box integrates the top mounted rotary preheater, side mounted heat exchanger and bottom mounted fluid bed cooler. The hot box will be fabricated in grade 321 stainless steel.